Home Inkjet Printer - UV INKJET PRINTER—-W5000 – Weiqian

Home Inkjet Printer - UV INKJET PRINTER—-W5000 – Weiqian Detail:

Parameters

| Product model | Inkjet Coding Machine –W5000 |

| Nozzle parameters | l Nozzle type: all imported industrial piezoelectric nozzles l Nozzle material: all steel l Maximum printing width: 54.1mm l Number of nozzles: 1280 l Nozzle row spacing: 0.55mm l Nozzle spacing: about 0.1693mm/column l Ink drop: 7~35Pl variable ink drop l Nozzle rows: 4 rows |

| Display screen | Size:10.1 inch |

| Touch screen | Resistive / Capacitive |

| Hardware interface | l USB2.0 interfacel RS232 interfacel Curing light interfacel Encoder interfacel Flip-flop interface |

| Defend degree | IP54 |

| Working environment | l Working temperature: 0 ℃-45 ℃ (best 10 ℃ ~ 32 ℃) l Humidity:15%-75% l Protection requirements: good grounding |

| Size | l Structure: stainless steel housing l Power supply: AC220V/50HZ l System power consumption: maximum power consumption 120W l Equipment weight: about 30kg l Machine size: 630*450*300mm l Nozzle size: 360*125*50mm |

| Technical specification |

l Nozzle life: 30 billion times of ink ejectionl Printing distance: 1mm-5mm, best 1-3mml Printing content length: 1.3ml Printing speed: 0-80 m/min (ink volume 1) (decided by factors such as material/resolution/environment/platform)l Longitudinal accuracy of nozzle: 600dpil Horizontal accuracy of print head: 600dpi-1200dpil Movement method: from left to rightl Printing direction: adjustable forward, reverse, vertical downward; adjustable up and down in the program, flip left and right l Curing type: LED-UV curing |

Features

l Font library support: built-in a variety of commonly used font libraries, in addition to support font import function, users can import their own fonts.

l Input method: support Pinyin input method, handwriting input method, etc.

l Secondary development: the software provides interfaces to support secondary development

l Material type: flat materials such as aluminum plate, ceramic tile, glass, wood, metal sheet, acrylic plate, plastic, leather, etc.

l Materials, bags, cartons and other products

l Applicable products: such as mobile phone displays, beverage bottle caps, food packaging bags, medicine boxes, plastic steel doors and windows, aluminum alloys

l Gold, batteries, plastic pipes, steel plates, circuit boards, chips, woven bags, eggs, brake pads, mobile phone shell cartons, motors, transformers, water meter inner plates, gypsum boards, PCB circuit boards, outer packaging, etc.

l Printing content: The system supports printing one-dimensional bar codes, two-dimensional bar codes, drug supervision codes, traceability codes, databases, Variable text, picture, logo, date, time, batch number, class and serial number, etc. And can be smart lively design the layout, content, and printing position.

2. Structure specification

| 1 | Handwheel: The host can be controlled to move up and down by shaking | 6 | Stand base |

| 2 | Bracket body: size scale on the side | 7 | Bracket fixing screws: screw down 4 fixing screws to fix the bracket, screw up to use the pulley |

| 3 | Horizontal axis | 8 | Host placement rack |

| 4 | Nozzle assembly | 9 | Inkjet printer host: inkjet printer operation interface |

| 5 | UV lamp: UV curing lamp can be mounted |

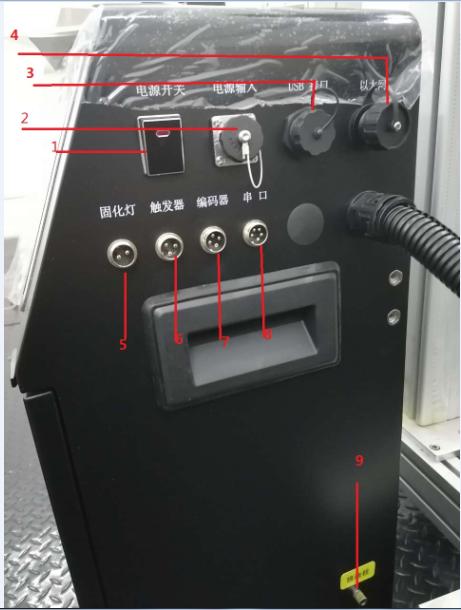

3. Interface specification

| 1 Power switch | 2 Power interface |

| 3 USB interface | 4 Ethernet interface |

| 5 Curing light interface | 6 Flip-flop interface |

| 7 Encoder interface | 8 RS232 Serial port |

| 9 Chassis grounding post |

Product detail pictures:

Related Product Guide:

The universal value of the electronic scale Internet of Things system not only needs to realize the integration and processing of weighing data, but also requires deeper exploration and mining of the data of the entire electronic scale system to fully satisfy production, supervision, service and even user psychology And other needs, to achieve the harmony and unity of equipment, network, production and people. Home Inkjet Printer - UV INKJET PRINTER—-W5000 – Weiqian , The product will supply to all over the world, such as: Mozambique, Turkey, Haiti, Company culture:Corporate vision: To become the leading brand in the global logo industry.Enterprise mission: Accelerate the process of human intelligence.Corporate values: Customer-centered, struggle-based, and integrity-based.Core culture: Create a platform for employees and create value for society.Corporate slogan: Smile embedded in life, intelligent embedded industry.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.